CNC Machining: A Dying Art

Where are all the skilled machinists? We’ve asked ourselves this question often as we scour our resources to find quality CNC machinists. Ones that aren’t already happily employed. True machinists that understand every part of the production process (from blueprints to finished product) are especially hard to find. But employers are paying a pretty penny for someone with their experience today. There are several contributing factors to the decline of machinists in the workforce. However, the demand hasn’t really changed. In fact, it’s growing.

According to the Bureau of Labor Statistics, the number of machinists and tool die makers is projected to increase by nearly 30,000 as we approach 2030. This is consistent with general occupation employment growth. The demand isn’t slowing down, just the supply.

While college is an appealing route for many high school graduates, it is hard to deny that trades are just as (if not more) lucrative than careers that require a 4-year degree. As we dive into the various CNC positions, you will see that being successful out of the gate is relatively easy. Especially for those who have the desire to put in the effort and want to work with their hands instead of at a desk.

What are CNC Machines?

Computer numerical control (CNC) machines are operated by pre-programmed computer software. This software tells the machine exactly what it needs to do to spit out a desired product. There are many types of CNC machines that can cut, drill, grind, or smooth a variety of materials from plastic to metal. The industries that most commonly use these machines are aerospace, transportation, defense, firearms, commercial, electronics, medical, optical, oil + gas, and marine.

CNC machines are crucial to the production process in many industries for creating prototypes, production parts, robot parts, machine components, furniture, and signage with maximum precision. Unfortunately, 3-D printers have failed to match the abilities of CNC machines thus far.

The History

CNC Machining, at its inception, was typically called “numerical control,” a system that didn’t initially involve a computer. The first official CNC machine was created in 1940. Inventor, John T. Parsons, discovered a way to calculate airfoil coordinates using a specific type of computer. This was the first computer numerical control machine that used punched cards as instructions for operation. The first CNC milling machine was created shortly thereafter in the 50s.

Since the 1950s, there have been many advancements in technology and computing that allow manufacturers greater accessibility to machines while requiring less skilled labor due to automation. Yes, technology advancements have changed requirements for skilled tradespeople in the field. But not all production facilities have made these advancements. Let’s look at the different skills required to program and run these machines [1].

CNC Programmers

This is where the machining process starts MOST of the time[2]. The programmer is responsible for using blueprints or models of components to create the code/program the machine will use to create the component. This job requires the skill to determine which kind of machine and tools to use to produce the component exactly right. Without getting too into the weeds, the programmer uses CAM (computer-aided manufacturing) or CAD (computer-aided design) software to translate the blueprints into a code (G-code) that the machine understands. As you can imagine, making a component out of raw material based on a visual requires extreme attention to detail, patience, and deep knowledge of CAD/CAM software and G-code [3].

What it takes to be a CNC Programmer:

- Several years of experience with machines (as a machinist or operator)

- deep knowledge of CAD software, CAM software and G-code

CNC Machinists:

The role of a CNC machinist is dependent on the type of machinery they are working with. Older machines require much more technical skill (less automation). A true machinist should be able to program the machine, run quality control, troubleshoot, or fix any mechanical issues, and supervise/manage the CNC Operators. While there is some overlap with a CNC Programmer as far as ability to read blueprints and program CNC machines, the machinist is hands-on with machines most of the time. Experience as a machine operator is typically a pre-requisite of this position, but going through training programs can accelerate the path towards becoming a machinist.

What it takes to be a machinist:

- Experience as a machine operator

- Management skills

- Knowledge of material properties

- Mathematic skills

- Programming + set-up of CNC machines

- Ability to read calipers and gauges

CNC Operators

There are two different types of Operators in CNC Machining. The first is a set-up operator, who is responsible for loading the program (from the CNC Programmer) on the machine, selecting appropriate tools, and then test-running the program to make sure it runs properly. A machine operator and a CNC machinist are synonymous in manufacturing and the terms get used interchangeably. The second, and more common, is the generic CNC Operator. Typically, operators are entry-level roles in CNC machining that serve as the foundation for a machinist role. The operator’s responsibilities differ depending on industry. Most operators spend their time setting up/calibrating and operating the machines as well as inspecting finished components to ensure the machine is running properly.

Machining Career Outlook

There is a large skill gap in manufacturing overall, but specifically presents itself in CNC Machining roles (3). There are several factors that contribute to this gap, one of which is the retiring baby boomers. Generations that came after the baby boomers did not feel the same draw to the trades. They pursued what seemed to be higher wages and better opportunity by earning bachelor’s degrees instead. Now, we find ourselves with 2 million open manufacturing positions in the coming 10 years, delayed production times, and lots of student loan debt [4].

The low supply of machinists is unfortunate for many companies that rely so heavily on production using these machines. However, it puts those with machining skills in a good spot for high earnings and job security. It truly is a job-seeker’s market right now and it doesn’t appear that it will change soon.

A Successful Career Path

Careers in CNC programming and operating offer a lot of variety in industry and location since it is vital to many kinds of manufacturing all over the country (and outside of it too) [3]. Another big reason to consider a career in machining is the salary. Even at the entry level, the wages are attractive. The current average hourly pay for CNC operators is $20.65, according to PayScale, and ranges from $15-29 per hour or $31-$64k annually. Most operator roles require no degree (a.k.a. no student loan debt) [5]! For CNC machinist roles, wages average $24.79 hourly or $75k annually [6]. And once the appropriate experience and skills are obtained, CNC programmers in the U.S. average $29.01 hourly/$75k annually [7].

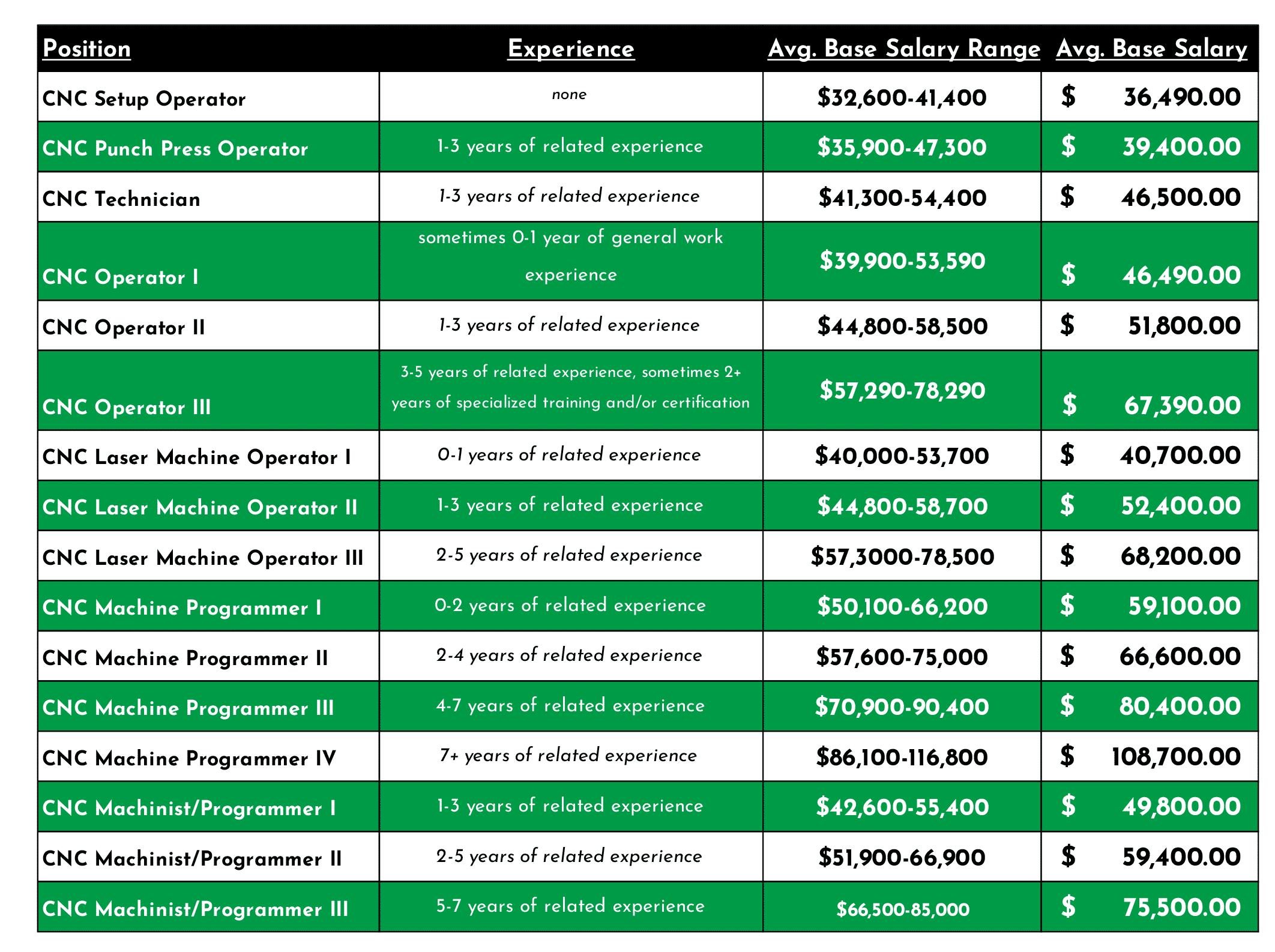

The great thing about all these positions is that the hourly wage or salary increases with experience (as seen in the chart below). There is plenty of opportunity to make more than the industry average.

Where We Step In

We have several customers across the country that we work with to hire the ever-rarer CNC operators, machinists, and programmers. If you’re interested in applying for a CNC position, check out the NCW job board to see current postings. Subscribe to the job updates so you can see when new CNC positions are posted. Maybe CNC isn’t your thing but you’ve got experience somewhere else in the manufacturing or warehousing world. You can still search all of our current job postings for a role that suits you, or submit a general application so you’ll be in our system when the right job does come up.

[job-feed num=’5′ order=’date-desc’ keywords=’CNC’ category=’C72492′][/job-feed]