Manufacturing Technician Salary Opportunities

What Do Manufacturing Technicians Do?

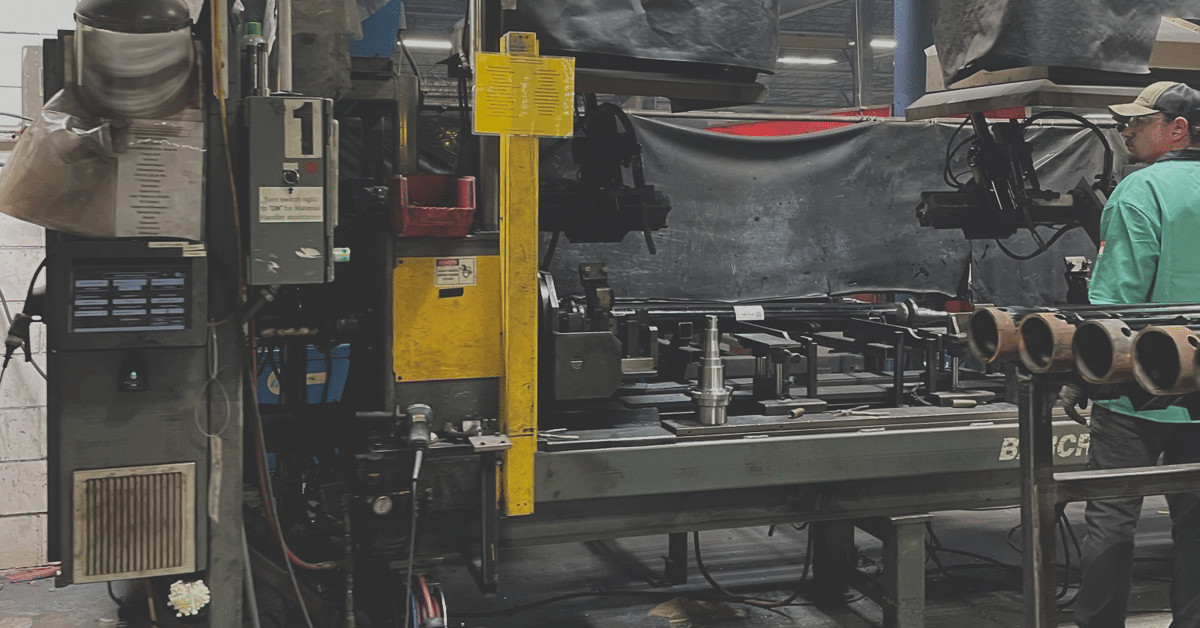

A manufacturing technician, or production technician, is a machine’s best friend. Any factory that produces physical goods likely needs manufacturing technicians to tend to the machinery. So, what do they do? Manufacturing technician responsibilities range from getting their hands dirty to data entry and quality control. A mix of skills is helpful for whoever takes on the responsibility of this role. The decisions technicians make can greatly impact the manufacturer—especially if they do not adhere to company protocol. Because this role is so integral to the manufacturing process, manufacturing technician salary opportunities are very enticing to those that do not want to pursue a college degree right after high school.

Manufacturing Technician Job Description:

- Monitoring & operating factory machines to produce an end product

- Performing machine functions according to company protocol

- Assessing machines regularly and performing routine maintenance

- Logging machine performance and product quality

Skills for success:

- Attention to detail

- Analytical skills

- Manual dexterity

- Problem-solving

Manufacturing Technician Education Requirements

Most employers do not require manufacturing technicians to have a college degree; however, education requirements vary by industry. Complex products may require an educational background in science or mechanics. According to Zippia, a little less than 40% have bachelor’s degrees, so it is safe to say that there are successful manufacturing technicians with only a high school diploma or GED. Technicians that obtain college degrees and beyond usually consider manufacturing technician roles a steppingstone in their career path. A compromise between a diploma/GED and a college degree is obtaining a manufacturing technician certification. Certifications offered by The Manufacturing Institute or NIMS can educate you on specific topics within manufacturing that may help you to land the job you want.

There aren’t specific manufacturing technician school programs that offer career training because roles are very industry (or product) specific. Most manufacturing technicians get trained on the job, even if they have past manufacturing or quality control experience. Those interested in manufacturing technology will usually study engineering, science, technology, or math to some capacity if they are looking to work for a particular type of manufacturer. Possessing background education that is applicable to a complex type of manufacturing (like pharmaceutical manufacturing) can open up opportunity for a higher manufacturing technician salary.

Manufacturing Technician Jobs

Over the last two decades, the number of production or manufacturing technician jobs has declined overall by about 8% according to Recruiter.com. But the good news is that the demand is projected to increase over the next 6 years at about 1.15% year over year. There will be an estimated 6,520 new jobs that will need to be filled by manufacturing technicians by 2029.

Geographically speaking, the states with the highest growth in demand for manufacturing technicians are Idaho, Nevada, West Virginia, Rhode Island, Virginia, South Carolina, and Texas. In contrast, the states with the highest concentration of production technicians are Texas, California, Minnesota, Michigan, Massachusetts, Ohio, and New York. Texas, being a major manufacturing hub, leads the pack with double the amount of employed technicians in California, the state with the second highest concentration.

The manufacturing technician career path is pretty straightforward but can take on many different nuances based on industry specialization. For the sake of understanding the overall progression of this career, we will look at the manufacturing production technician career path very generally. Each level highlighted below assumes compensation changes in proportion to growth in experience, training, and responsibility. All core competencies remain the same throughout the progression, but the complexity of those competencies increases along with ability to be independent while performing duties.

Skills & core competencies: machine operation, machine programming & manufacturing, numerical control, precision measurement, quality inspection, reading blueprints and diagrams, safety policies and procedures, record keeping, standard operating procedures (SOP).

Career Progression

Entry Level : Manufacturing Technician I (Production Technician I)

At this stage, there is little-to-no experience in manufacturing. The highest amount of education necessary to complete the job is a high school education.

Mid-Level: Manufacturing Technician II (Production Technician II)

Intermediate or mid-level manufacturing technicians have one to three years of experience under their belt, but still do not manage people. Most technicians at this stage will have obtained an associate’s degree or specialized training certifications in a field that is relevant to the industry they wish to pursue.

Senior Level: Manufacturing Technician III (Production Technician III)

Senior level manufacturing technicians have had experience ranging from two to five years. They have completed further education that allows them to be proficient in multiple competencies relating to the job. This person works independently, but still reports to a supervisor and does not typically manage others.

Manufacturing Technician IV (Production Technician IV)

Once someone has reached the senior IV level, they have been in the trade anywhere from 5-7 years. The biggest difference between this level of seniority and the Manufacturing Technician III is the ability to perform complex duties independently with little guidance. There isn’t necessarily a requirement for further education to reach this level, but depending on industry expertise, production technicians will seek bachelor’s degrees in electronics or engineering to qualify for a better manufacturing technician salary.

Production Manager

The manufacturing technician career path can eventually lead to high-paying opportunities in production management. These roles often require a bachelor’s degree (though not always) in a related field like supply chain management, manufacturing management, or industrial engineering.

Manufacturing Technician Salary

Manufacturing technicians can make good wages after just a few years of experience. Let’s look at compensation for each phase of the production technician career path. All salaries are calculated based on the U.S. general industry average. The bonus target percentages are the 50th percentile, meaning half of the population that does the role makes up to that target bonus percentage.

Entry Level Manufacturing Technician Salary

Average base: $41,200

Bonus Target percentage: 5%

Mid-Level Manufacturing Technician Salary

Average base: $47,200

Bonus Target percentage: 5%

Senior Manufacturing Technician Salary

Average base: $54,500 – $61,500

Bonus Target percentage: 5%

Production Manager Salary

Average base: $118,600

Bonus Target percentage: 12%